According to foreign media reports, scientists from the U.S. Department of Energy's Pacific Northwest National Laboratory,PNNL) of the U.S. Department of Energy have found a new way to take advantage of this prospect, but there are also many problems with energy storage components. Silicon is usually used in computer chips and many other products. Because the charge per gram of silicon is 10 times that of graphite, it has attracted much attention. The problem is that silicon will expand rapidly when encountering lithium, and it is too fragile to bear the pressure when manufacturing electrodes.

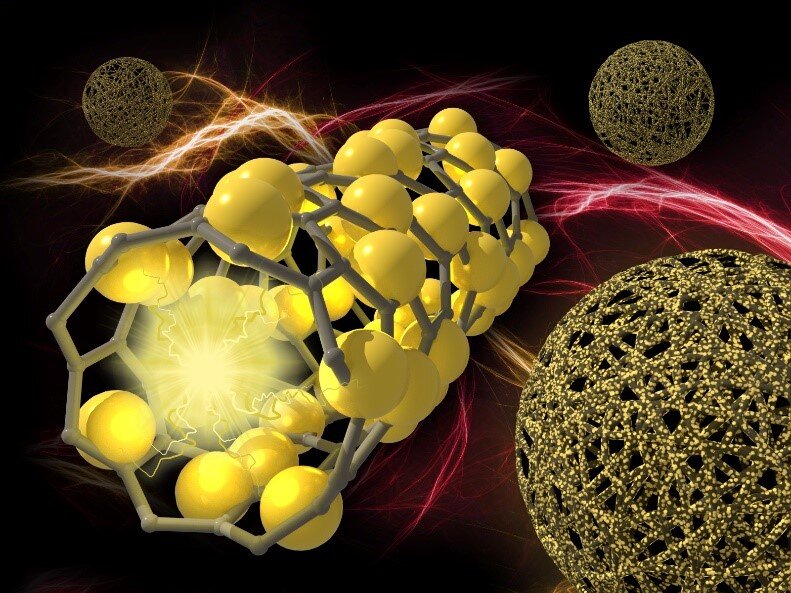

(Photo source: Northwest Pacific National Laboratory)

In order to solve such problems, PNNL researchers have developed a unique nano-structure that can limit Silicon expansion and strengthen it with carbon. The study may provide a new electrode material design for other types of batteries and ultimately help to improve electric car, electronic equipment and other equipment lithium ion battery energy capacity.

As a conductive and stable carbon, graphite is very suitable for filling lithium ions into the anode during charging. Compared with graphite, silicon can absorb a lot of lithium, but its volume will also expand 3 times, resulting in anode rupture. Researchers gathered tiny silicon particles into microspheres (about the size of a red blood cell) with a diameter of about 8 microns to create porous silicon.

Researchers said: "For example, solid materials such as stones will crack if their volume expands too large. The structure we have created is more like sponge, and there is space inside to absorb and expand."

The study found that when the charge is twice more than that of the ordinary graphite electrode, the thickness change of the porous silicon structure electrode is less than 20%. Different from the previous porous silicon, thanks to the carbon nanotubes that make the microspheres become like gauze balls, the microspheres also show extraordinary mechanical strength.

Researchers developed the structure in several steps by coating silicon oxide on carbon nanotubes. Next, the nanotubes are put into a milk liquid of water and oil, and then heated to boiling. Researchers said: "When water evaporates, carbon nanotubes coated with silicon oxide will condense into balls. Then, silicon oxide is converted into silicon with aluminum and higher heat, and then immersed in water and acid to remove derivatives." This process will produce a powder composed of tiny silicon particles on the surface of carbon nanotubes.

Researchers used atomic force microscope probes to test the strength of the porous silicon ball. The results showed that the nano-sized yarn ball would produce slight bending and lose some pores under very high compression force, but it does not break.

This result is a good sign for the commercialization of this kind of material, because anode material must be able to bear the high compression force of roller in the manufacturing process. Researchers said that the next step will be to develop more scalable and economical methods to produce silicon microsphere so as to produce a new generation of high-performance lithium ion batteries in the future.