Waste biomass is not only an environmental pollutant, but also a renewable raw material. Pyrolysis is one of the important technologies of waste biomass resource utilization. Renewable bio-oil, bio-carbon and a part of thermal hydrolysis gas can be obtained through biomass pyrolysis under anoxic conditions. However, at present, there are two key problems that seriously hinder the commercial application of the pyrolytic technology. One is that the pyrolytic bio-oil is unstable and easy to age and deteriorate, and the composition is complex and difficult to separate and improve the quality. The other is that the product value in the pyrolytic process is low, products lack market competitiveness.

In order to solve this problem, the research group of Jiang Hong, a professor of China University of Science and Technology, cooperated with the research group of Yu Hanqing, through coupling rapid pyrolysis, atmospheric distillation and chemical vapor deposition technology, high calorific value and stable solid phase biological coal (bio-coal) and high performance carbon nanomaterials (less-layer graphene and carbon nanotubes) have been successfully prepared respectively, it provides important technical support for the commercial application of waste biomass pyrolysis technology.

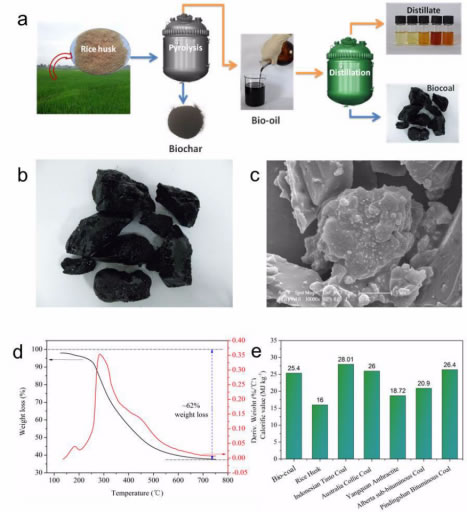

bio-oil obtained from the pyrolysis of biomass raw materials (agricultural and forestry wastes and organic solid wastes, etc.) is a renewable resource. Researchers at home and abroad have been committed to the catalytic upgrading and separation of biooil, expect high value-added chemicals or high-quality fuels. However, the composition of bio-oil is complex and unstable and usually contains hundreds of organic compounds. In the catalytic process, some organic matters undergo condensation, dehydration, coking and other reactions, resulting in catalyst failure, making the catalytic upgrading process difficult to continue. At the same time, the common separation methods, such as atmospheric distillation or Molecular distillation, make bio-oil Coke rapidly, which hinders the further distillation. The research group found that a new solid fuel (named biological coal, bio-coal) can be obtained by controlling the parameters of atmospheric distillation process and realizing the rapid coking of biooil. The analysis shows that the calorific value of biological coal obtained from different biomass raw materials (rice husk, sawdust, wheat straw, bagasse, soybean straw, etc.) is 25-28MJ/kg, which is equivalent to that of commercial coal. Moreover, biological coal has environmental friendliness such as stable performance, low sulfur content and no heavy metals. The model study also shows that the production potential of biological coal in China can reach 402 million tons of standard coal. The results are Bio-coal: An renewable and massively producible fuel from lignocellulosic biomass was published in Science Advances(Sci. Adv., 2020,6, eaay0748). The co-first authors of the thesis are doctor Cheng Binhai and doctor Huang Baocheng of the School of Chemistry and materials.

In addition to bio-oil, the high temperature gas generated during the pyrolysis process has not been fully utilized. The analysis results show that the thermal hydrolysis gas contains small molecules of carbon organic matters, and the thermal hydrolysis gas temperature is relatively high, which is a potential precursor for preparing carbon nanomaterials. By optimizing the pyrolysis conditions, researchers can not only use model biomass raw materials (lignin and cellulose) to heat and dissolve the gas, but also directly use waste biomass (sawdust and wheat straw) without cooling and purifying the heat and decompress the gas. 3D graphene (3DGF) was prepared by thermal decompression by chemical vapor deposition. By changing the pyrolysis deposition conditions, carbon nanoparticles can be obtained. These high value-added carbon materials demonstrate good performance in pollutant removal and energy storage. Compared with traditional graphene vapor deposition, the results of life cycle assessment (LCA) show that the synthesis of graphene by biomass thermal hydrolysis gas has less environmental impact and energy consumption. The relevant research results are published in the journal Sustainable production of value under the title Nature Sustainability-added carbon nanomaterials from biomass pyrolysis. The co-first author of the thesis is Zhang Shun, a master student of the School of Chemistry and materials, and Jiang Shunfeng, a doctoral student. This study is of great significance to improve the value of waste biomass pyrolysis products and thus promote the commercialization of pyrolysis technology.

The above research is funded by the general project of the National Natural Science Foundation of China.

Figure 1. Biological coal preparation route and product characterization. a. The technical route of preparing biological coal from waste biomass pyrolysis. B and c, SEM photos of biological coal. d. Thermogravity analysis of biological coal. e, the calorific value comparison between different biological coals and some commercial coals.

Figure 2. Schematic diagram of the route for preparing high value-added carbon nanomaterials from waste biomass pyrolysis.

FIG. 3. (a) Raman spectra of 3D graphene prepared by pyrolysis of waste biomass. (B) XPS spectra of 3D graphene. c (cellulose) and d (lignin), 3D TGA-FTIR spectra of gas phase products of model biomass pyrolysis.