I. Overview of wave absorbing materials

Stealth technology is a modern military technology that makes it difficult to be found, identified, tracked and hit by controlling and reducing the detectable signal characteristics of military targets. It is divided according to the detection wave used, stealth technology can be divided into visible light stealth technology, radar stealth technology, infrared stealth technology, laser stealth technology, etc. Radar, as the most reliable means to detect military targets, is used in a proportion of more than 60%. Therefore, the research on stealth technology is based on and focuses on radar stealth technology and is developing towards multi-functional and high-performance stealth.

The key of radar stealth technology is to try to reduce the radar cross-sectional area of the target. Its main means are shape stealth and material stealth. Material stealth refers to the extensive use of wave-absorbing materials on aircraft. wave-Absorbing material (Electromagnetic wave Absorbing Materials) refers to the Electromagnetic wave that can absorb the attenuation incident and through the dielectric oscillation, Eddy current, magnetostrictive and other effects of the absorber, the Electromagnetic energy is converted into heat energy and dissipated, or a kind of functional materials that make electromagnetic waves disappear due to interference.

According to different standards, the classification of wave-absorbing materials is different. According to the different forming process and bearing capacity of the wave-absorbing materials, they can be divided into coated wave-absorbing materials and structural wave-absorbing materials; According to the different wave-absorbing principles, they can be divided into two types: absorption type and interference type.

Second, nano carbon fiber used for wave absorbing materials

With the improvement of stealth technology's requirements on the performance of wave-absorbing materials, the research and development of new absorbent has become the focus of wave-absorbing materials research. The development of new generation stealth weapon equipment puts forward higher and higher requirements on the thickness, density, wave-absorbing band and wave-absorbing performance of wave-absorbing materials. Traditional absorbent can no longer meet this demand, and new absorbent must be found.

In terms of the development of wave-absorbing materials, fiber wave-absorbing materials have unique shape specificity and mechanical properties, and are a kind of wave-absorbing materials with great development prospects. At present, fiber commonly used as absorbent includes carbon fiber, silicon carbide fiber and magnetic metal fiber, among which carbon fiber can not only be used as structural wave-absorbing material, but also its short fiber can be used as absorbent of coated wave-absorbing material; compared with silicon carbide fiber, carbon fiber has the advantage of low density, so it is widely used.

Nano carbon fiber refers to the carbon fiber of 50~200 nm grown in gas phase. It not only has the characteristics of low density, high specific modulus, high specific strength and high electrical conductivity of carbon fiber grown in general gas phase, but also has few defects, it has the advantages of large specific surface area, good electrical conductivity and compact structure, so it is not only an electrical loss type material, but also a magnetic loss type material, it can be prepared into coated and structural materials or high-performance structural wave-absorbing materials, and is also a better microwave absorption and electromagnetic shielding material.

Figure 1 micro fraction of carbon nanofibers

Figure 2 SEM photo of carbon nanofibers

Third, spiral carbon nanofibers are used for wave-absorbing materials

Spiral uses acetylene, ethylene, methane, propylene, benzene and so on as carbon sources, and Ni,W,Ti,Fe,Co, mo and other transition metal element powder, polar plate and its compounds are prepared as catalysts. Different process parameters lead to different forms of spiral carbon nanofibers.

Spiral nano carbon fiber is a typical chiral material. Chiral means that there is no geometric symmetry between the object and its image, and the object cannot coincide with the image through any operation. The biggest characteristic of chiral materials with chiral structure is the cross polarization performance of electromagnetic field, that is to say, alternating electric field can not only cause the electrode of materials but also cause the magnetization of materials. Chiral material is a new type of electromagnetic functional material, which is synthesized by uniformly mixing random oriented chiral bodies into a certain base material. Compared with common electromagnetic materials, an important property of chiral materials is that they can cause cross polarization between electric field and magnetic field and can be used as wave-absorbing materials.

In addition, because the microstructure of spiral carbon nanofibers is different from that of carbon nanotubes dominated by graphite crystals, its grain size has a certain distribution range, and the corresponding electromagnetic wave has a wide resonance matching frequency, produce the effect of broadband; The specific surface area is large, and the surface atoms have higher activity. It is easy to absorb the energy of electromagnetic wave to the excited state, and then jump to release energy in other ways; in particular, the characteristic of chiral helix distortion of spiral carbon fiber itself is that surface atoms are more easily excited, so the wave absorption performance of spiral carbon fiber is higher than that of carbon nanoparticles and ordinary fibers. Based on the above conditions, spiral nano-carbon fiber is a very excellent wave-absorbing material.

In a word, as a new type of chiral wave-absorbing material, spiral nano-carbon fiber has shown certain advantages. It is the main task today to better use spiral nano-carbon fiber as wave-absorbing material to realize the goal of radar stealth technology.

IV. Preparation of spiral carbon nanofibers

1) preparation

In CVD method, nano-scale superfine Ni particles can effectively play the role of transition group metals, making hydrocarbons undergo high temperature cracking to produce purer spiral carbon nanofibers. Because the growth process of spiral carbon nanofibers in gas phase is relatively complex, their growth morphology is also very different.

The regular form of helical carbon nanofibers prepared by CVD method can be observed as follows: single helical carbon nanofibers and double helical carbon nanofibers. Among them, the double helix nanometer carbon fiber is formed by winding two fibers with the same rotation direction and the same growth rate, and its shape is similar to the double helix structure of DNA molecules.

The following methods can be used to prepare spiral carbon nanofibers in the laboratory stage:

Carbon source: industrial acetylene, molecular formula C2H2;

Catalyst: nano-scale superfine nickel powder with a particle size of 30 ~ 200nm;

Growth Promoter: thiophene, chemically pure, molecular formula: C4H4S, volatile liquid;

Carrier gas: high purity hydrogen with purity over 99.999%;

Protective gas: nitrogen;

Tubular electric furnace: Model LY-1, thermocouple horizontal verification furnace;

Intelligent temperature controller: HN-2000-type precision intelligent temperature controller.

The detailed experimental parameters are determined as follows:

① matrix (or substrate), the matrix is generally graphite sheet;

② carbon source, acetylene has the best decomposition effect and the highest efficiency. Acetylene is used as carbon source here, and the flow rate is about 37.5 ml/min;

③ the carrier gas is hydrogen, and the flow rate is about 62.5 ml/min;

④Catalyst, there are many kinds of catalysts, but only when nickel powder is used as catalyst can spiral nano carbon fiber be prepared; ⑤Sulfur compounds as growth promoter, such as thiophene, etc;

⑥ reaction temperature, the general reaction temperature is about 1008K;

⑦ The reaction time varies according to different substrates, generally 30min.

2) characterization

Scanning electron microscope (SEM) was used to analyze the morphology and purity of spiral carbon nanofibers;

The structure of spiral carbon nanofibers was characterized by Raman spectral analysis;

Qualitative phase analysis was performed using X-ray diffraction spectra.

Five, the preparation of nano carbon fiber wave-absorbing materials and wave-absorbing performance test

The performance testing technology of wave-absorbing materials is an essential research method of radar wave-absorbing materials. The performance testing methods of radar wave-absorbing materials mainly include the measurement of electromagnetic parameters of absorbent and reflectivity of wave-absorbing materials. In addition, density, stability and price are also important parameters to measure the performance of wave-absorbing materials.

Once the radar absorbing material is designed and manufactured, it needs to be tested and identified to determine whether the absorbing material meets the design index requirements. The performance of radar absorbing materials is mainly expressed by reflectivity. Applicable Test methods include NRL bow method, RCS method, etc. The test system determines the frequency band of the test according to people's needs, generally above GHz, typically 2~18GHz, the lower one will be several hundred MHz, and the higher one will even reach 40.110GHz.

Structural stealth materials are basically composite materials. Epoxy resin is selected as the matrix, and the prepared carbon fibers are evenly ground. After filtering and screening by standard sieve, they are evenly dispersed into epoxy resin to prepare composite materials, to test its wave absorption performance.

In order to improve the scientificity of the experiment, the electromagnetic parameters of the wave-absorbing materials in the X band should be tested first, and the wave-absorbing performance of the composite materials in this band should be simulated through computer programming. On this basis, single-layer structural wave-absorbing materials were prepared and their wave-absorbing properties were tested.

1) preparation of nano carbon fiber/epoxy resin waveguide samples

Weigh carbon nanofibers of a certain quality, add them into epoxy resin, and mechanically stir them at room temperature to make them fully mixed evenly. Then add dispersant, curing agent and defoaming agent to it. After ultrasonic dispersion, place it in the mould and solidify it at room temperature for 6 hours. Take out the sample and polish it properly, that is, the X-band electromagnetic parameter test standard sample of carbon fiber/epoxy resin composite material is obtained. The specifications are: length 22.86mm, width l0.16mm, height 4mm. The specific process is shown in Figure 1:

Fig. 3 preparation process of nano carbon fiber/epoxy resin waveguide sample

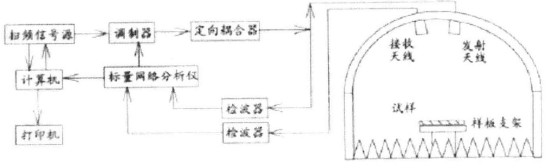

Use vector network analyzer to measure the electromagnetic parameters of the material indirectly with the prepared nano carbon fiber/epoxy resin waveguide sample and the measurement range: 8~12GHz. The measuring system is shown in Figure 2:

Figure 4 schematic diagram of X-band electromagnetic parameter testing system

Using computer program to carry out simulation calculation, the best thickness of single-layer structure wave absorbing material is obtained. (Simulation process)

1) Refer to the computer simulation results to prepare nano carbon fiber single-layer structure wave absorbing materials

Nanometer carbon fiber/epoxy resin mixture was prepared according to the above method. Place the glass plate horizontally on the experiment table, and cover the surface of the glass plate with organic silicon demoulding paper. Add the carbon fiber/epoxy resin mixture mixed evenly, lay the glass fiber cloth, repeat the above two steps until the composite material reaches the required thickness. Then cover a piece of organic silicon demoulding paper, cover the glass plate and apply IMPa pressure, and solidify and form it for 24 hours at room temperature. According to the provisions of the test standard GJB2038-94, the sample is processed into a square sample with an area of 180mm × 180mm.

2) reflectivity (wave absorption performance) test

The prepared composite materials were tested for reflectivity by using vector network analyzer and bow method. Measurement range: 2~18GHz, the principle of measurement system is shown in Figure 3:

Figure 5 test schematic diagram of reflectivity bow method

VI. Existing problems

Carbon fiber is used as wave-absorbing material, which has dual functions of bearing and reducing the reflection cross section of radar wave, and is a kind of wave-absorbing material with very promising development.

Although great progress has been made in the research of carbon fiber, it is far from meeting the requirements of stealth technology for "thin, light, wide and strong" wave-absorbing materials. At present, the wave-absorbing band of carbon fiber wave-absorbing materials is still limited to 8~18GHz, and the thickness of wave-absorbing materials is over 3mm, which still has great improvement potential. At present, the wave-absorbing carbon fiber is developing in two directions: one is developing in the direction of broadband, so that the carbon fiber can be absorbed in a wider frequency range; The other is aiming at a certain frequency band or frequency point, in this frequency band, high absorption effect is achieved; And thin and lightweight are the common goals pursued by these two development directions.

Due to the geometric structure of the spiral and the cross polarization caused by the coupling of electricity and magnetic when interacting with electromagnetic waves, the spiral hand sign may become a wave-absorbing material with good performance.